How is Smart Glass Made?

We are often asked 'How is Smart Glass Made?' by customers wanting to understand the wider technology. Due to the sheer diversity of the Switchable Smart Glass range, the answer to this question is not a simple one, with various products demanding different manufacturing processes to create them.

Smart Glass technology comes in 2 main forms; Switchable Smart Glass and Switchable Smart Film, both bringing different advantages and benefits to their customers. In this post, we will be taking a look into the various types of Switchable Smart Glass products, their composition and the special conditions necessary to enable production. In doing this, we will shed light on how the products are made, how they work and how we get them to you.

What is Switchable Film?

Switchable Film, (also known as Switchable Smart Film or PDLC Film) is a technology that is capable of adjusting light transmission through the application of an AC power source. The active component in Switchable Film (PDLC - Polymer Dispersed Liquid Crystal) consists of liquid crystal microdroplets which are suspended in polymer. The natural state of the film sees the PDLC molecules arranged in a way that causes light waves to refract through and reflect away from the surface, distorting the state of the glass to present as frosted. When an electrical current is passed through the PDLC layer, the liquid crystal molecules polarise, allowing light to pass through.

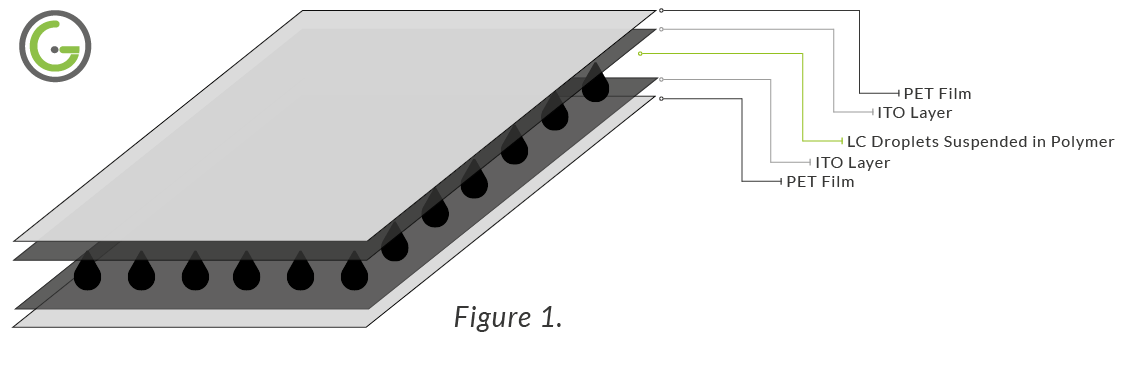

As Figure 1 shows, standard PDLC technology is composed of multiple layers to create this incredible product.

The outer layers are an optically clear protective coating - a polyethylene terephthalate (PET) film. This encloses / protects the film and its PDLC core whilst still allowing for optical transparency.

The 350 micron ITO film - a conductive Indium Tin Oxide layer - enables an electrical current to pass through the PDLC core safely, again, whilst allowing for striking optical clarity so as not to distort the technology's effect.

The 100 micron PDLC core comprises of liquid crystal droplets that are suspended in polymer and then enclosed in the ITO film to allow for the electrical current to pass through it.

Achieving consistency in the manufacture of switchable PDLC film is both a science and an art. Many suppliers have come and gone during our time, and we are justifiably proud of our track record.

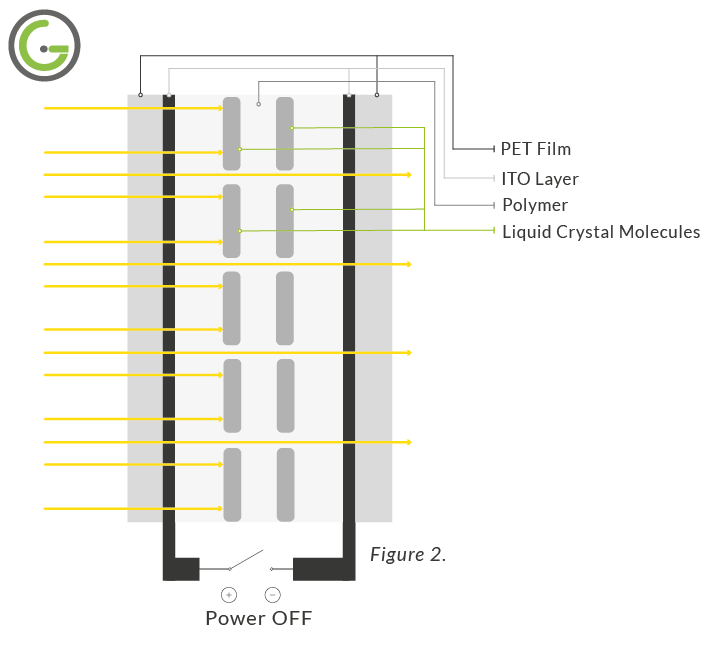

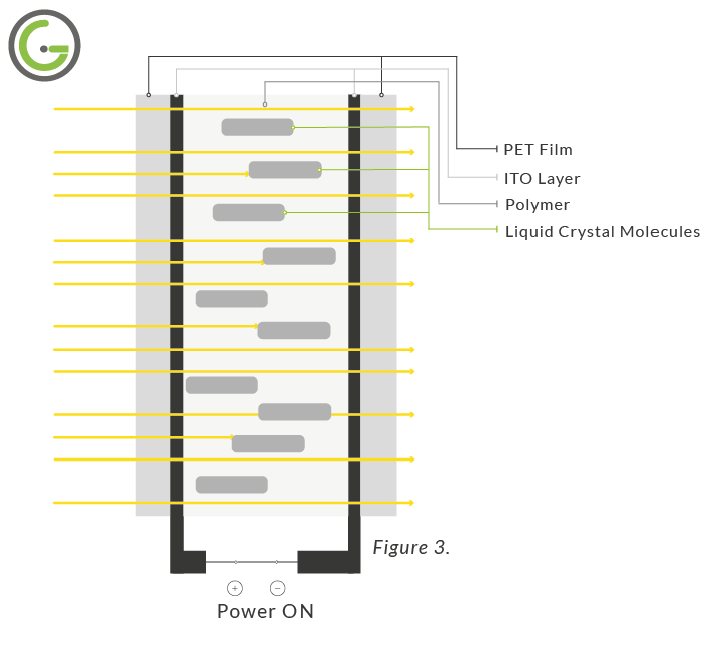

Figures 2 & 3 demonstrate how the technology works. From Figure 2, we can see that with an absence of electrical current, the natural state of the film is frosted. The liquid crystals in the PDLC core are naturally arranged in a way that blocks out a lot of the light that would pass through it otherwise. However, one of the benefits of this technology is that it is not a complete black-out technology, blocking out around 33% of the light whilst allowing some of the ambient light to penetrate the layers.

Figure 3 displays the technology when it is switched on, where we can see that almost all of the light is able to permeate through the film as the product presents clear. Due to the nature of the technology, switchable glass is not as optically clear as standard glass and may still present with a slight haze. Whilst clarity is a very important variable we work towards, a degree of haze is a normal manifestation of the product, especially from an angular perspective.

Switchable Glass

Switchable Film is designed for application to glass or plexiglas, and recent years have given rise to the development of numerous switchable products that make the most out of the substrate being used.

One of the most common uses of PDLC film is in the production of Switchable Glass, which takes such forms as -

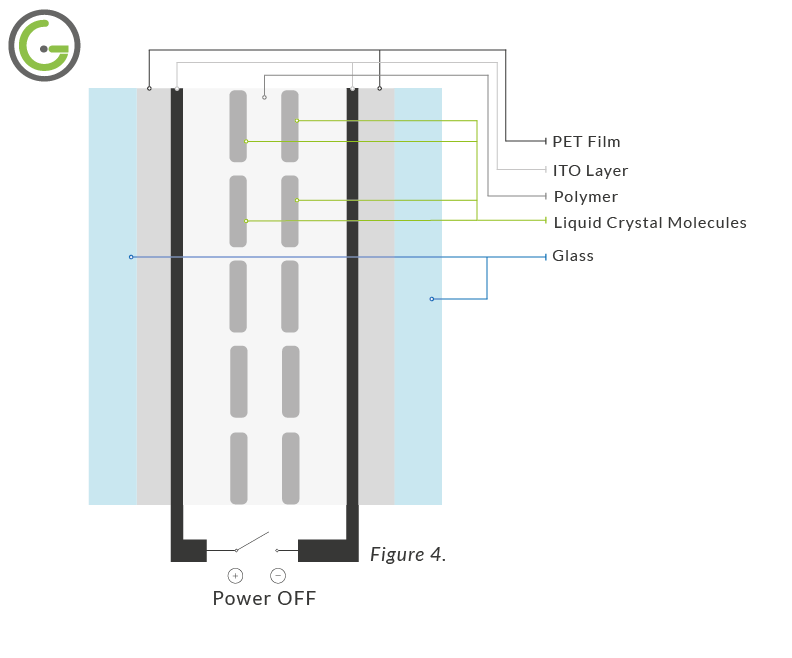

Switchable Laminated Glass (Figure 4)

Laminated safety glass ideal for high traffic areas, bathrooms and hospitals. The Switchable layer is fully encased between the 2 pieces of glass.

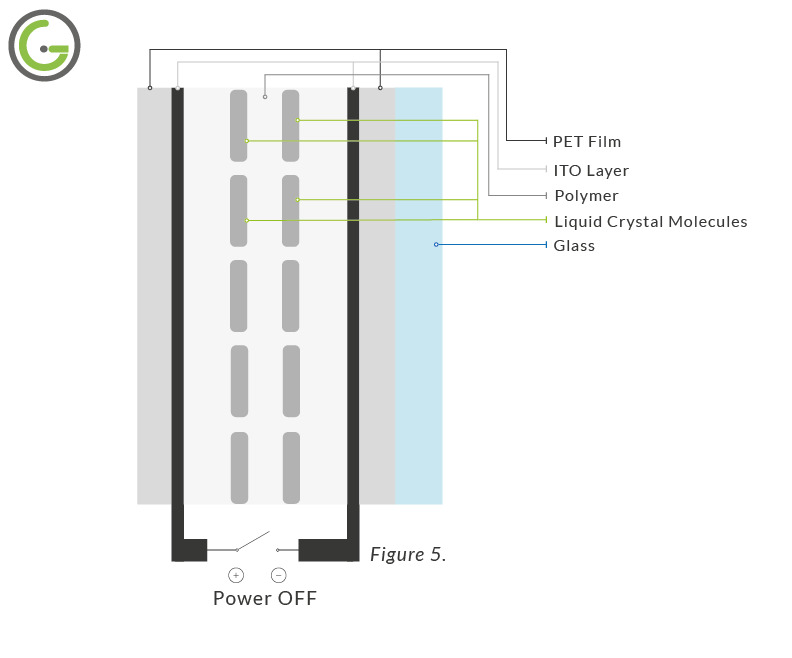

Toughened Switchable Glass (Figure 5)

The switchable optical layer is factory-coated using UV light to any thickness of glass. Ideally suited for projection applications.

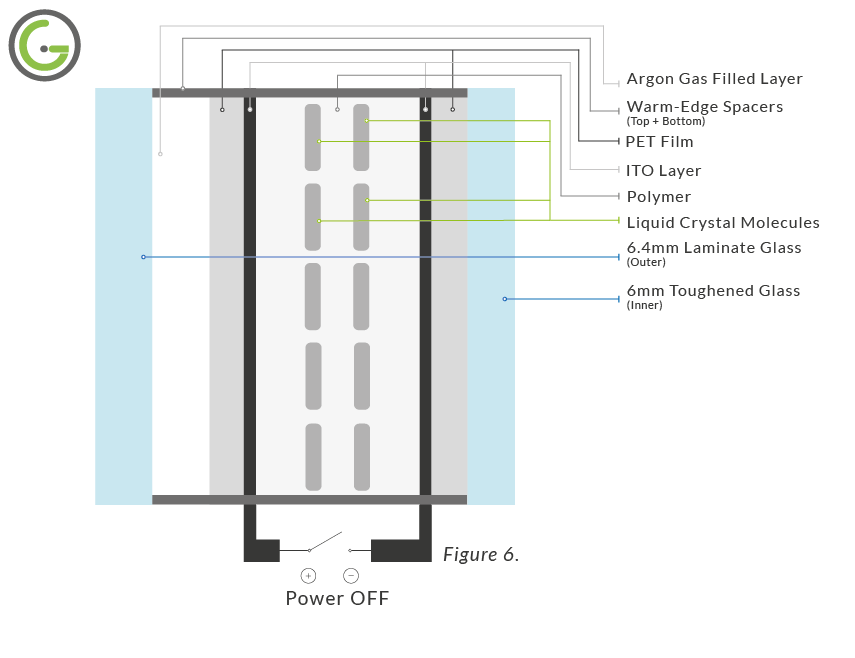

Switchable Double Glazing (Figure 6)

Energy efficient double glazed units with integral switchable film layer. Ideal for both external and internal windows for commercial building and homes.

Switchable Vision Panels (Figures 4-6)

Battery powered switchable vision panels for integration into doors & partition wall.

Self-Adhesive Switchable Film

Previous versions of switchable film were manufactured for professional application by lamination to glass, restricting both usage and price.

However, in recent years, we have seen numerous developments of switchable technology such as higher clarity, faster switching, improved reliability, greater consistency, and purer crystal dispersion.

Intelligent Glass have dedicated themselves to developing their specialist technology to bring the market the next generation in switchable technology - retrofit Self-Adhesive Switchable Film.

Next Generation PDLC Technology

Designed specifically to retrofit to existing transparent surfaces like glass or plexiglas, Self-Adhesive Switchable Film by Intelligent Glass provides a simple and cost effective alternative to previous switchable film technologies.

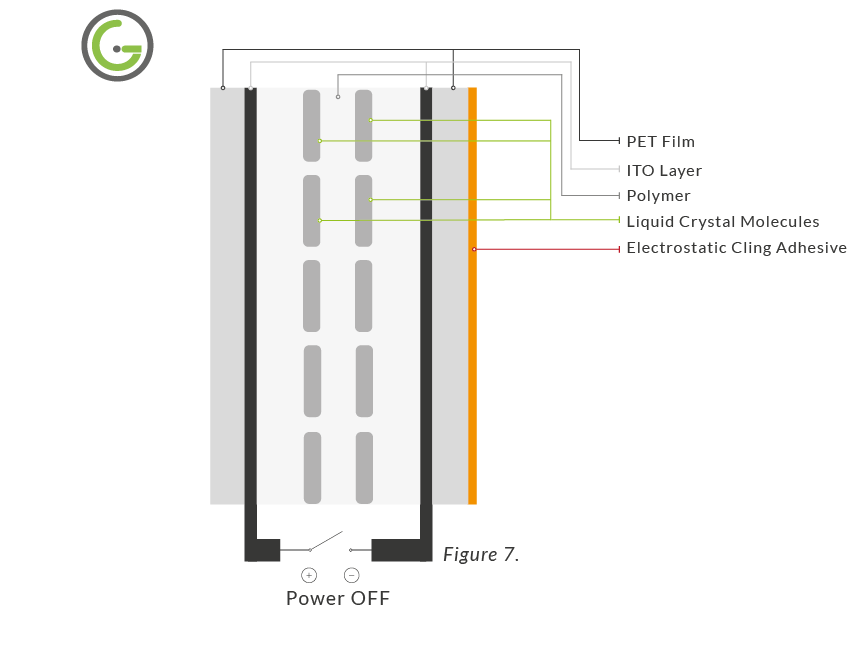

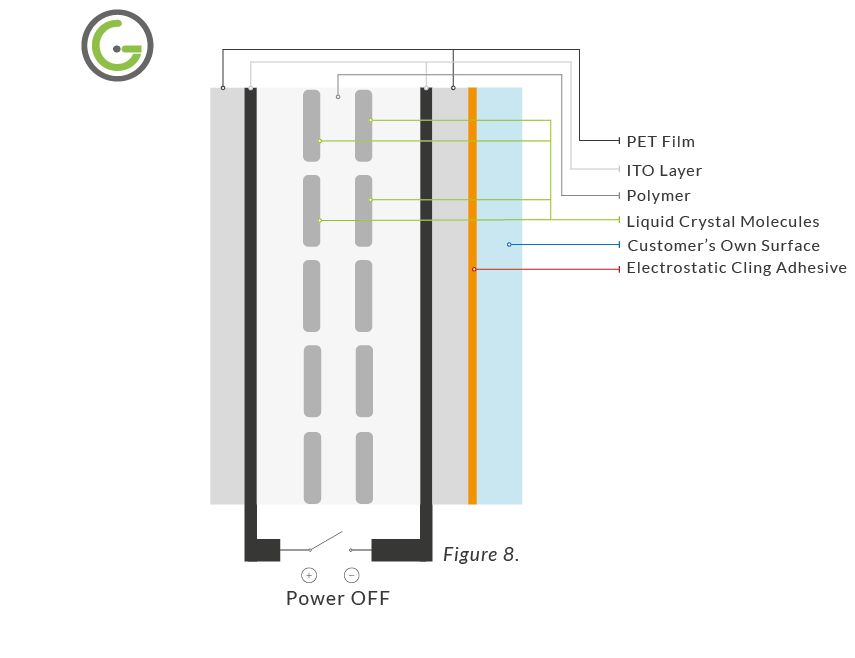

Its main point of difference to previous switchable products is that it is manufactured with a self-adhesive cling layer on one side (Figure 7), which allows for a peel and stick application. This simple difference enables customers to apply switchable technology to both new and existing surfaces without specialist installation equipment required (Figure 8).

The film works in the same way as standard switchable products - a simple ON - OFF mode switches the film from being clear to frosted in an instant.

Intelligent Glass have refined a manufacturing process that allows us to offer Self-Adhesive Switchable Film in custom shapes and sizes up to 1500mm in width. What's more is that multiple pieces can be joined together to grant large transparent surfaces switchable functionality.

Industry Leading Manufacturing Facilities

The manufacturing process of previous switchable technology forced early innovators to invest in the highest quality manufacturing facilities. Even the slightest imperfection in the raw materials or manufacturing process could result in a substandard switchable product, making quality and control a highly important consideration for manufacturers of switchable technology.

Intelligent Glass are proud to have industry leading manufacturing facilities that has enabled us to produce the highest quality switchable products for over a decade, building an illustrious reputation and working with some of the world's leading brands.

The manufacturing sensitivities of switchable technology not only require expert handling, but also manufacturing facilities that meet exacting requirements.

Intelligent Glass offers the promise that all Switchable Glass products are manufactured in a 'clean room' environment, minimising the risk of manufacturing imperfections ensuring the customer receives the very best product possible.

Our switchable technology is manufactured on-site using the latest in manufacturing equipment which enables us to offer the sheer range of products that we produce. From our DGU (Double Glazed Units) production bay to our product testing environments, Intelligent Glass production facilities boast the highest quality output and specification available on the market.

Care from Start to Finish

Intelligent Glass offers a full crating and shipping service for UK and worldwide export. The fragility of switchable products necessitates that they are exported in protective wood crates, keeping them safe and secure in transit.

The bespoke nature of many switchable products means that shipping crates are usually individually made to accommodate the size of each unique order.

Robust and designed with protection in mind, our crates are equipped to safeguard glass, film and accessories during its journey across the world.

Why Choose Us?

Intelligent Glass has been specified by some of the world’s leading brands.

Want more reasons why you should choose us? View our brochure to learn why you should choose Intelligent Glass.